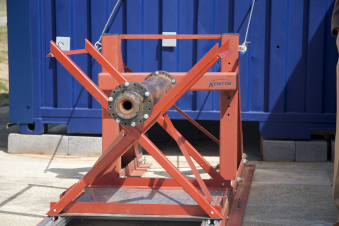

A dedicated rocket engine test facility supports the testing of bi-propellant and hybrid rocket engines up to 5kN thrust in a safe and secure test environment. Tests are conducted remotely from a spacious control cabin, using an automated control system for precise timings, with data logged electronically from a range of sensors. The facility supports a variety of ignition methods, including an oxygen-propane spark torch. It can accommodate any non-toxic propellant combinations and supply the majority of common propellants (with advance notice).

A well-equipped workshop is available for last-minute engine modifications or repairs.

All testing is undertaken by our dedicated team with many years of experience with rocket engine technology and testing. The team is available to provide technical consultancy from engine design and test campaign planning through to post-firing analysis if required. The facility is ideal for university rocketry teams, SMEs wishing to trial low TRL propulsion technology such as novel propellant combinations, and may also be used to support teaching and training courses.

Services

Rocket Propulsion Testing

Space Environment Testing

The Space Laboratory area offers space environment testing and related services, aiming at low-TRL technology development, proof-of-concept, and R&D services.

Our Lab offers a Thermal Vacuum Chamber capability with support for a wide range of operating temperatures and cycling between them, to support space environment testing. Alongside this we offer Launch Simulation services, using our in-house 10g centrifuge system, and vibration table system; and a Structural Test Frame up to 10kN for tests on structural components.

Testing facilities do not require samples or equipment to be constructed to cleanroom standards before arrival, but an optional Cleanroom facility can be activated on request, rated to ISO7 standards.

Launch Rail & Range Control

The Space Technology Test Centre offers flight test activities for rocket powered vehicles on site, taking advantage of the two launch rail systems. UAVs using other propulsion systems are also supported for rail launch.

A 4m mobile launch rail offers flexible vertical or angled launch options for smaller vehicles, taking advantage of the site’s restricted airspace up to 6,000 feet vertically, ideal for university rocketry societies and competition events.

A larger fixed launch rail, variable up to 12m length and any launch angle between vertical and horizontal, offers launch options for access to the adjacent Danger Area over Cardigan Bay, and options for connecting to the larger D201 Danger Area over the Irish Sea, taking advantage of the maritime radar system on site and the Mission Control area, offering secure telemetry and communications within the site, and connections to off-site on request.

Structural Testing

The testing laboratory at the Snowdonia Space Centre contains a 4.0m x 1.2m reaction frame for the testing of lightweight structural elements such as wing spars or even complete wings of small aircraft and drones, rocket vehicle fuselage sections, light steel framing members for a variety of applications and structural panels. It is also ideally suited to the testing of building envelope systems, including external cladding sheets, liners, deck profiles and spacer systems. In addition to the reaction frame, there is also sufficient covered space to build bespoke test frames for applications such as down-slope loading on standing seam roofs and strain gauging on airframes.

Training

The Snowdonia Space Centre offers a unique training facility for university students, recent graduates and new entrants to the space industry. Unlike most academic courses, which are mostly theoretical by necessity, the Snowdonia Space Centre can provide hands-on, practical training in space laboratory testing, rocket propulsion and flight operations, in addition to being the perfect venue for delegates requiring a broad introduction to the space industry.

The teaching and training facilities are available to host academic modules for universities or as a venue for third-party training providers, in addition to bespoke training courses for industry given by the centre's experienced technical staff.

Bespoke Test Equipment

For many years Newton has designed and manufactured its own test equipment and has experience across a range of testing scenarios from static testing of structural members to rocket propulsion testing. Newton also builds its own control and datalogging hardware and writes its own software. Newton is pleased to offer this capability as a service to businesses and academia who require their own bespoke test equipment to meet specific needs that are not routinely catered for by off-the-shelf test apparatus. Newton's experienced team of engineers will visit the client's premises to discuss their precise testing requirements and then design, build and install the equipment for the client. On-going technical support is available, including advice on test procedures and certification.

Specialist Engineering Consultancy

Newton specialises in support for manufacturers wishing to bring new products or concepts to market or extend an existing range of products or services across a variety of applications and sectors. This includes specialist design services, advice on physical testing, generation of product performance data for manufacturers' technical literature and specialist engineering consultancy services. Newton's team includes expertise on aerospace structures, building structures and systems (especially building envelope solutions), design for manufacturing and electronics for control and communications systems. Newton also has its own in-house software capability, specialising in advanced engineering software such as structural engineering, thermal modelling and space mission analysis.